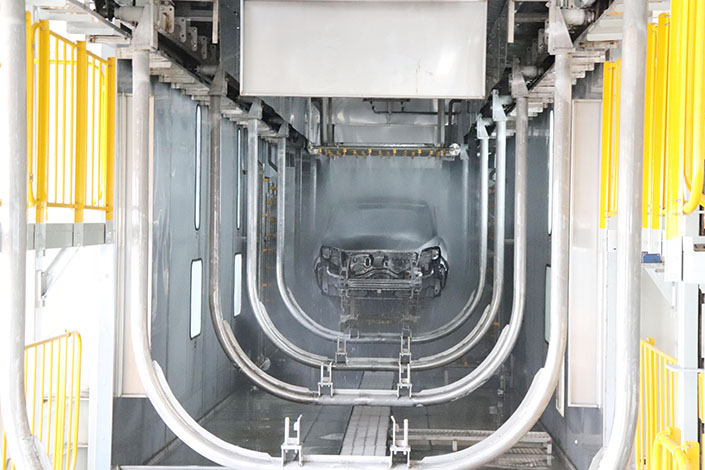

Uhlobo lwe-spray yokukhiqiza umugqa wokukhiqiza ngaphambi kokwelashwa

Ukwelashwa kwangaphambili kokumboza kuhlanganisa ukwehlisa (ukwehlisa), ukususwa kokugqwala, ukwenza izingxenye ezintathu ze-phosphating.I-Phosphating iyisixhumanisi esiyinhloko, ukukhishwa kwe-degreasing kanye nokugqwala kuyinqubo yokulungiselela ngaphambi kwe-phosphating, ngakho-ke ekusebenzeni kokukhiqiza, akufanele nje sithathe umsebenzi we-phosphating njengokugxila, kodwa futhi siqale kusukela kuzidingo zekhwalithi ye-phosphating, senze umsebenzi omuhle ngaphezu kwalokho. uwoyela nokugqwala ukususwa, ikakhulukazi naka ithonya mutual phakathi kwabo.

Ukunciphisa ukuvuvukala

Ngokuthuthuka kwezimboni, ukuvikelwa kwemvelo kanye nokuthuthukiswa kwezimo zokusebenza sekuyinto evamile kubantu.Ngakho-ke, isidingo sokuvikelwa kwemvelo kufanele sinakwe lapho kukhethwa ama-ejenti.Ngakho-ke, ukukhethwa kwe-ejenti yokukhipha amafutha kudinga ukulungiswa okulula, ikhono lokuqeda amandla liqinile, aliqukethe i-sodium hydroxide, i-silicate, i-OP emulsifier nezinye izakhi okunzima ukuzihlanza ekamelweni lokushisa, ukugeza kalula ekamelweni lokushisa, aliqukethe ubuthi. izinto, zingakhiqizi amagesi ayingozi, izimo zokusebenza ezinhle.Ukukhethwa kwe-rust remover kudinga ukufakwa kwabagqugquzeli, ama-corrosion inhibitors kanye nama-inhibitors, kungathuthukisa isivinini sokususwa kokugqwala, kuvimbele i-workpiece kusuka ekugqweni ngokweqile kanye ne-hydrogen embrittlement, ingavimbela kangcono inkungu ye-asidi.Kuyafaneleka ikakhulukazi inkungu ye-asidi evimbela, eyenzeka ngesikhathi sokuqoqa inkungu ye-asidi, ukugqwala kwemishini nesitshalo, hhayi nje ukungcolisa imvelo, futhi kungabangela ukubola kwamazinyo, ububomvu be-conjunctival yamazinyo, izinyembezi, ubuhlungu, umphimbo owomile, ukukhwehlela kanye nezinye izimpawu. , ivimbela ngempumelelo inkungu ye-asidi, hhayi nje kuphela isidingo sokuvikelwa kwemvelo, noma ngenxa yempilo ezidingweni zesisebenzi.

Ukugeza amanzi

Ukugeza ngemva kokususwa kwamafutha nokususwa kokugqwala, nakuba kungokwenqubo yokusiza ngaphambi kokudweba, kudinga futhi ukubangela ukunakwa okwanele.Ngemuva kokususwa kwamafutha nokususwa kokugqwala, ingaphezulu le-workpiece kulula ukunamathela kwamanye ama-surfactants angewona ama-ionic kanye ne-CL-.Uma lezi zinto eziyinsalela zingahlanzwa kahle, zingabangela ukuncipha kwefilimu ye-phosphating, ukonakala okuqondile, ngisho ne-phosphating.Ngakho-ke, ukuthuthukisa ikhwalithi yokugeza amanzi ngemva kokususwa kwamafutha kanye nokususwa kokugqwala, kuyadingeka ukuthi udlule ama-rinse amaningi, ama-rinses amabili, isikhathi se-1-2min, futhi njalo esikhundleni samanzi ukuze uqinisekise ukuthi inani le-PH lamanzi liphakathi kuka-5-7. .

I-Phosphating

Okubizwa ngokuthi phosphating, libhekisela workpiece metal ngemva equkethe dihydrogen phosphate ukwelashwa isixazululo, ukusabela kwamakhemikhali futhi ebusweni bayo ukukhiqiza ungqimba ezinzile insoluble phosphate ifilimu, ifilimu ibizwa ngokuthi ifilimu phosphating.Inhloso eyinhloko yefilimu ye-phosphating ukukhulisa ukunamathela kokugqoka nokuthuthukisa ukumelana nokugqwala kokugqoka.Ziningi izindlela zokwenza i-phosphating, ngokwezinga lokushisa le-phosphating, zingahlukaniswa zibe izinga lokushisa eliphezulu le-phosphating (90-98 ℃), izinga lokushisa eliphakathi nendawo (60-75 ℃), izinga lokushisa eliphansi le-phosphating (35-55 ℃) kanye nezinga lokushisa elivamile. i-phosphating.

Passivation

Ubuchwepheshe be-passivation befilimu ye-phosphating busetshenziswa kabanzi eNyakatho Melika nasemazweni aseYurophu.Ubuchwepheshe be-passivation busekelwe ezicini zefilimu ye-phosphating ngokwayo.Ifilimu ye-phosphating incane, ngokuvamile ku-1-4G / m2, umkhawulo awukho ngaphezu kwe-10g / m2, indawo yamahhala ye-pore inkulu, futhi ukumelana nokugqwala kwefilimu ngokwayo kunqunyelwe.Abanye ngisho nenqubo yokomisa ku-rust ephuzi esheshayo, ngemuva kwe-phosphating i-passivation ivaliwe ukwelashwa, ingaba ifilimu ye-phosphating pore evezwe nge-oxidation yensimbi, noma ukwakheka kwe-passivation layer, ifilimu ye-phosphating ingadlala ukugcwaliswa, i-oxidation, yenza ifilimu ye-phosphating izinze endaweni. umkhathi.

Ukomiswa kwefilimu ye-phosphating

Ukomisa ifilimu ye-phosphating ingadlala izindima ezimbili, ngakolunye uhlangothi, ukulungiselela inqubo elandelayo yokususa amanzi ebusweni befilimu ye-phosphating, ngakolunye uhlangothi, ukuthuthukisa ukumelana nokugqwala kwefilimu. ngemva kokugqoka.

Ukusungula umugqa wokwemboza ngaphambi kokwelashwa, ukwakheka kwenqubo kufanele kuqedwe ngaphambi kokuklama, ukukhiqizwa nokufakwa kwemishini engajwayelekile.Ngakho-ke, ukwakheka kwenqubo kuyisisekelo somugqa wokukhiqiza, futhi umzila olungile nonengqondo uzoba nomthelela omuhle ekusebenzeni kokukhiqiza kanye nekhwalithi yomkhiqizo.

Isetshenziselwa zonke izinhlobo zomdwebo we-workpiece, amanye amamodeli angenziwa ngokwezifiso.