I-pre - manual yokwelapha inqubo elula kanye nenqubo yokwelapha yangaphambi kokuzenzakalelayo, le yakamuva ihlukaniswe isifutho esizenzakalelayo kanye ne-automatic dip spray izinqubo ezimbili.I-workpiece kufanele iphathwe ngaphezulu ukuze kukhishwe amafutha nokugqwala ngaphambi kokufafaza.Kulesi sigaba kusetshenziswe uketshezi oluthe xaxa, ikakhulukazi isikhiphi sokugqwala, i-ejenti yokuhlanza, ukulungiswa kwetafula, i-phosphating agent nokunye.

Esigabeni sokucubungula noma i-workshop ngaphambi komugqa wokukhiqiza umdwebo, ukunakwa kufanele kukhokhwe ekusungulweni kokuthengwa okudingekayo, ukuthutha, ukugcinwa nokusetshenziswa kwesistimu ye-asidi eqinile kanye ne-alkali, ukuhlinzeka abasebenzi ngezingubo zokuzivikela ezidingekayo, ukugqoka okuphephile nokuthembekile, ukuphatha, ukumiswa kwemishini, kanye nokuthuthukiswa kwezinyathelo zokwelapha izimo eziphuthumayo kanye nezinyathelo zokuhlenga uma kwenzeka izingozi.Okwesibili, esigabeni sokulungiswa komugqa wokukhiqiza umdwebo, ngenxa yokuba khona kwenani elithile legesi engcolile, uketshezi olulahlwayo nezinye izinto ezintathu ezingcolile, ngakho-ke ngokwezinyathelo zokuvikela imvelo, kuyadingeka ukulungisa ukuphuma komoya, ukukhishwa kwe-liquid kanye imishini emithathu yokuhlanza imfucuza.

Ikhwalithi ye-workpiece eselashwe ngaphambilini kufanele yehluke ngenxa yesisombululo esihlukile sokwelashwa kanye nenqubo yokukhiqiza yokumboza.Ukucutshungulwa okungcono kwe-workpiece, uwoyela ongaphezulu, ukugqwala okufanele ukwenze, ukuze kuvikelwe isikhathi esifushane ukugqwala futhi, ngokuvamile kufanele kube ku-pretreatment ngemuva kwezinqubo ezimbalwa, i-phosphating noma ukwelashwa kwe-passivation: ngaphambi kokufafaza impushana, kufanele futhi ibe nesiqeshana sokusebenzela se-phosphating. okomisa, kumswakama wayo ongaphezulu.Ukukhiqizwa kweqoqo elincane elilodwa, ngokuvamile kusetshenziswa ukomiswa komoya kwemvelo, ukomisa ilanga, ukomiswa komoya.Futhi ngobuningi bomsebenzi wokugeleza, ngokuvamile kuthatha ukomisa izinga lokushisa eliphansi, usebenzisa ihhavini noma umgwaqo owomisa.

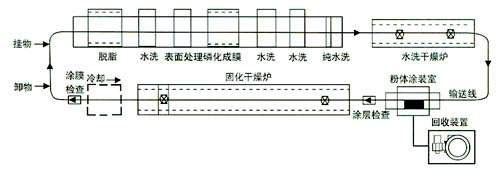

Ukukhiqizwa kwenhlangano ye-powder coating

Okweqeqebana elincane lokusebenzela, idivayisi yokususa uthuli eyenziwa ngesandla ngokuvamile iyamukelwa, kanti inqwaba yokusebenzela yenqwaba, ithuluzi lokuthungula elizenzakalelayo noma elizenzakalelayo livame ukusetshenziswa.Ukuthi uthuli lwenziwa ngesandla noma oluzenzakalelayo, ukulawula ikhwalithi kubaluleke kakhulu.Ukuqinisekisa ukuthi sishaye workpiece powder umfaniswano, ukushuba engaguquki, ukuvimbela isifutho mncane, ukuvuza spray, Sula off kanye nezinye iziphambeko.

Umugqa wokukhiqiza we-Coating inqubo, kodwa futhi kufanele unake ingxenye ye-hook ye-workpiece, ngaphambi kokungena ekwelapheni, kufanele unamathele ku-powder yayo ngangokunokwenzeka uzoshaya, ukuvimbela ukuphulukiswa kwe-powder okweqile kwe-hook, okunye ukuphulukisa ukususa impushana esele. ngaphambi kobunzima, kufanele kube okufika ngesikhathi ukuhlubula hook has okuqinile powder ifilimu, conductive ukuqinisekisa hook muhle, kanye nenani zobuciko ukuze powder.

Ukuphathwa kokukhiqizwa kwenqubo yokuphulukisa emgqeni wokugcoba

Le nqubo kufanele sinake: workpiece olufuthwe, uma inqwaba encane yokukhiqiza olulodwa, singene esithandweni sokuphulukisa ngaphambi kokunaka ukuvimbela powder falling, ezifana powder bezihlikihla mkhuba, kufanele kube okufika ngesikhathi spray powder.Lapho ubhaka, inqubo eqinile kanye nezinga lokushisa, ukulawula isikhathi, qaphela ukuvimbela umehluko wombala, ukubhaka ngokweqile noma isikhathi esifushane kakhulu esibangelwa ukuphulukiswa okwanele.

Ukuze uthole inani elikhulu lokulethwa okuzenzakalelayo kwe-workpiece, emgwaqeni owomisa ngaphambi futhi uhlole ngokucophelela ukuthi ukuvuza kwesifutho, ukufutha into encane noma i-powder yasendaweni, njengezingxenye ezitholakalayo ezingafanelekile, kufanele ivalwe ukuze kuvinjelwe ukungena emgwaqeni owomile, ngangokunokwenzeka yehlisa isifutho.Uma i-workpiece ngayinye ingafaneleki ngenxa yesifutho esincane, singafafazwa kabusha futhi siqiniswe futhi ngemva kokwelashwa.

Isikhathi sokuthumela: Jan-17-2022